The Polycarbonate

Evolution is a light illuminating all facts,

a curve that all lines must follow…

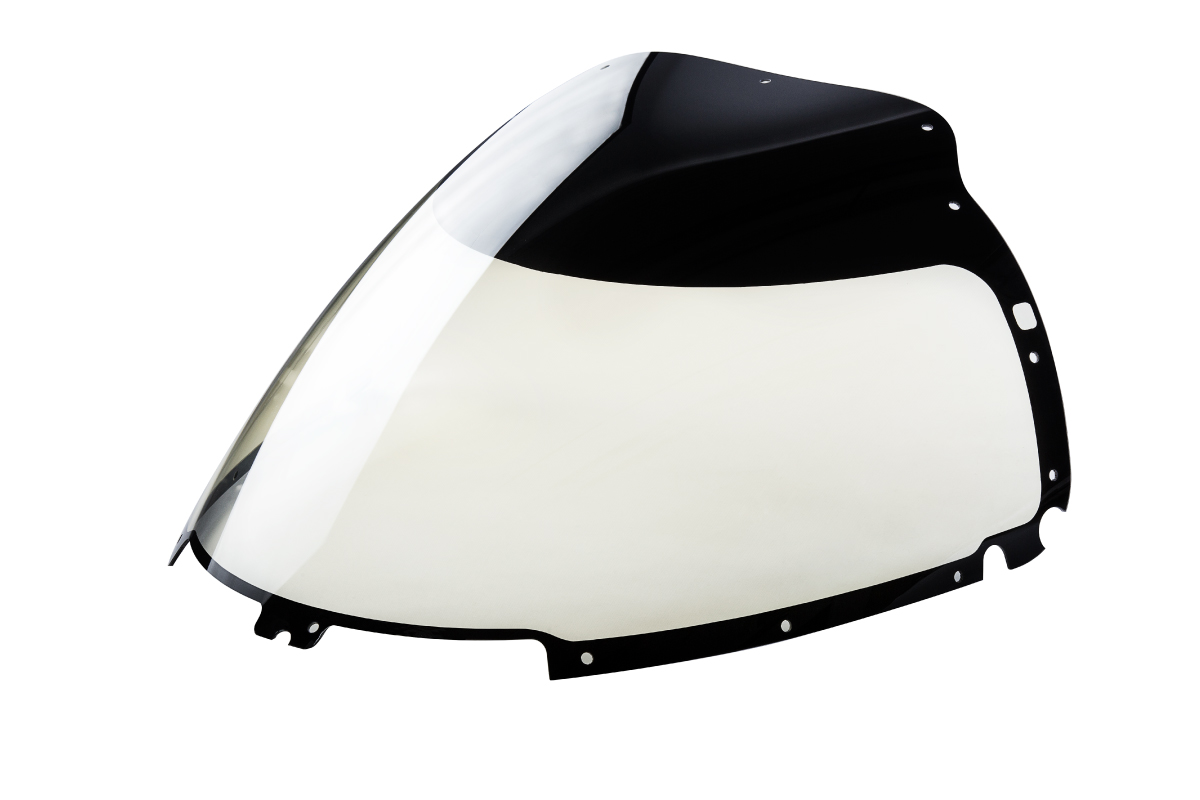

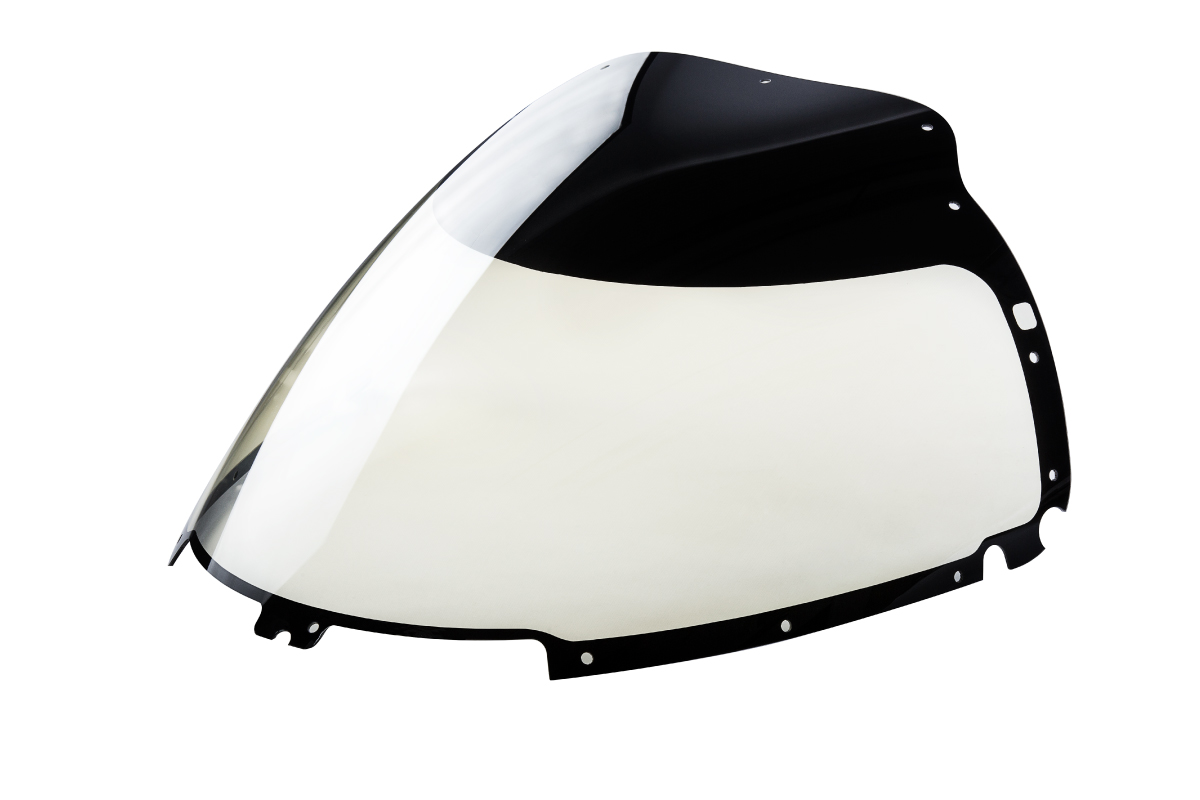

Polycarbonate is an innovative material that has been a success thanks to its qualities of lightness, transparency, resilience and mechanical resistance.

Benefitting from the most modern polycarbonate thermoforming systems available, Viraver is able to produce complex, lightweight shapes with state-of-the-art functional features while ensuing excellent optical quality.

Viraver’s polycarbonate products have met with great success particularly in the automotive industry, where highly renowned brands demand a product that reflects their success.

Process

Thermoforming

A polycarbonate windscreen is based on a suitably dimensioned and profiled flat sheet. The thermoforming process involves giving the flat sheet a curved surface. This takes place by means of a thermal process which gives the polycarbonate a curved form. To ensure the highest visual quality, each particular plastic after bending is tested optically, it is that it forms part of a monolithic product or a layered product.

Silkscreen Printing

Silkscreen printing is a process that serves both aesthetic and functional purposes, as it helps to safeguard the quality of the bonding. It is made through printing by screen printing frames and appropriate inks of compact and shaded bands on glass or plastic interlayer.

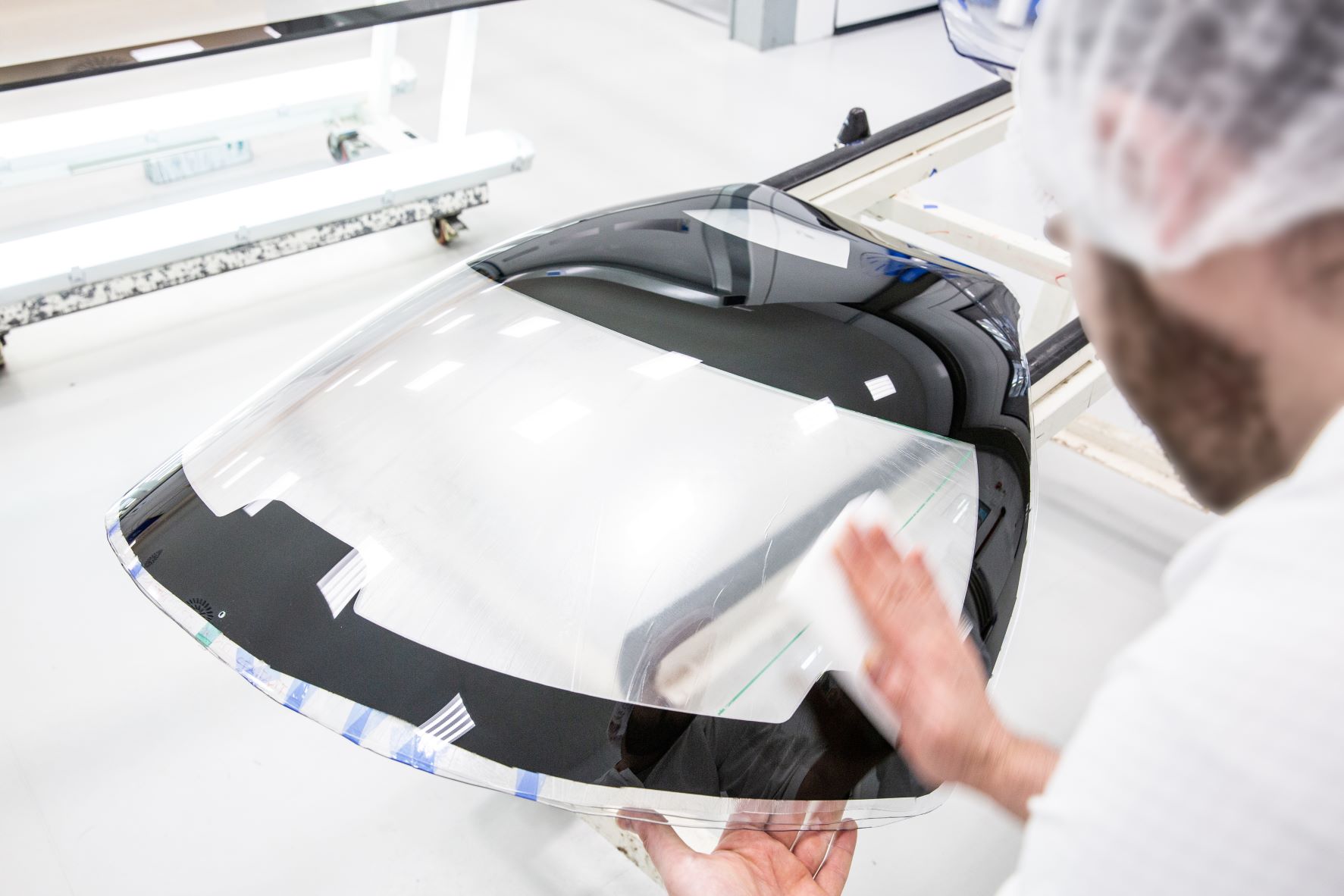

Clean Room Assembly

Silkscreen printing is a glass printing technique which serves both aesthetic and practical purposes. At Viraver, we use two printing technologies: CLASSICAL SILKSCREEN PRINTING • Which involves printing by means of silkscreen frames and inks on compact and shaded, black and coloured strips, which protect the glues used to install the glass, while at the same time creating an attractive aesthetic effect in the combinations of glass and structure. PRINTING ON PVC • Viraver is a Kuraray licensee for SentryGlass® Expression™, a type of technology which enables high definition coloured images to be printed continuously on both transparent and opaque interlayers.

Autoclave Lamination

This is the process in which the union between the glass and the polycarbonate material that make up the stratified takes place. In Viraver lamination is carried out in an autoclave, which consists in subjecting the laminate to the simultaneous action of pressure, temperature and vacuum in order to generate the intimate union of the materials. Viraver is equipped with a new large autoclave for polycarbonate last equal to 29.53ftx10.83ft (9mx3,30m), in addition to the existing one.

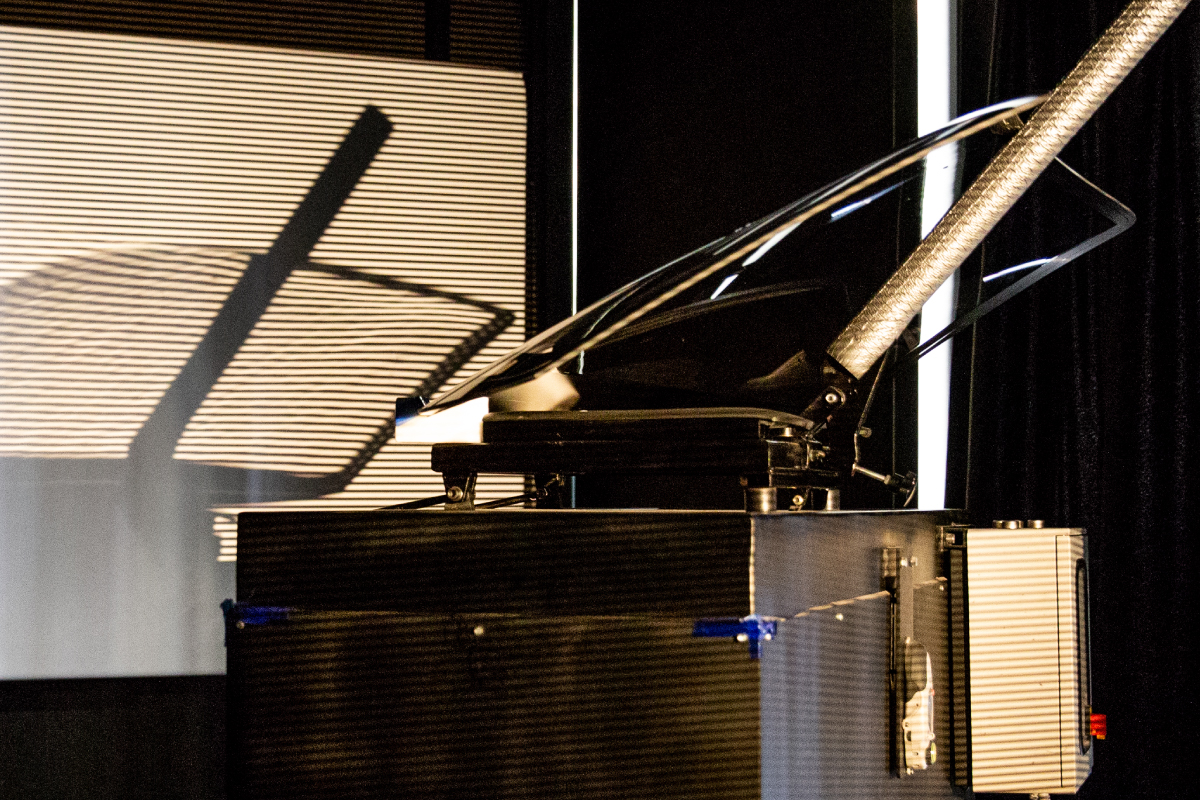

Five Axis Machine

When manufacturing polycarbonate windscreens and windows, it is necessary to remove the excess materials left over from the previous processes to obtain the shapes and sizes required by the customer and guarantee a perfect fit at the moment of assembly. Such activity is carried out through the use of a five-axis machine that allows to trim the perimeter and/or to employ other processes such as perforations, incisions or notches. 19.68ftx10.83ft (6mx3,3m).

Final Testing

Polycarbonate windscreens have to guarantee maximum visibility for the driver, and this requires careful checking and testing. Viraver has a testing chamber in which it is possible to reveal distortion and optic deviations in the windscreens in accordance with the international standards in force: • DIN 50-305 • ECE – UN R-43

Technologies

Infrared Filter

Viraver has the means to research, based on functionality and needs, shielding glass against infrared radiation, to reduce the effect of sun radiation up to 55%. In order to achieve this, Viraver uses shielding solutions through the use of special interlayers or selective films incorporated within the plastic interlayer.

Anti-Scratch Coating

The fundamental feature of plastics is their ductility and lightness. Unfortunately, they tend to deteriorate in the course of day-to-day use.

Signs of this deterioration include scratches, opacity and yellowing.

To increase the durability of polycarbonate products, Viraver has developed a special anti-scratch coating which hardens the surface and makes it much more resistant than the original product. The product acquires the required hardness imposed by international norms (ECE R43 e DOT).

Infrared Filter

Viraver has the means to research, based on functionality and needs, shielding glass against infrared radiation, to reduce the effect of sun radiation up to 55%. In order to achieve this, Viraver uses shielding solutions through the use of special interlayers or selective films incorporated within the plastic interlayer.

Anti-Scratch Coating

The fundamental feature of plastics is their ductility and lightness. Unfortunately, they tend to deteriorate in the course of day-to-day use.

Signs of this deterioration include scratches, opacity and yellowing.

To increase the durability of polycarbonate products, Viraver has developed a special anti-scratch coating which hardens the surface and makes it much more resistant than the original product. The product acquires the required hardness imposed by international norms (ECE R43 e DOT).